Vertical or horizontal hammer mills are grinding equipment to reduce the size of the processed product. Adaptable to different types of material, from cereals, cosmetic products, plastics, waste for recycling, among others.

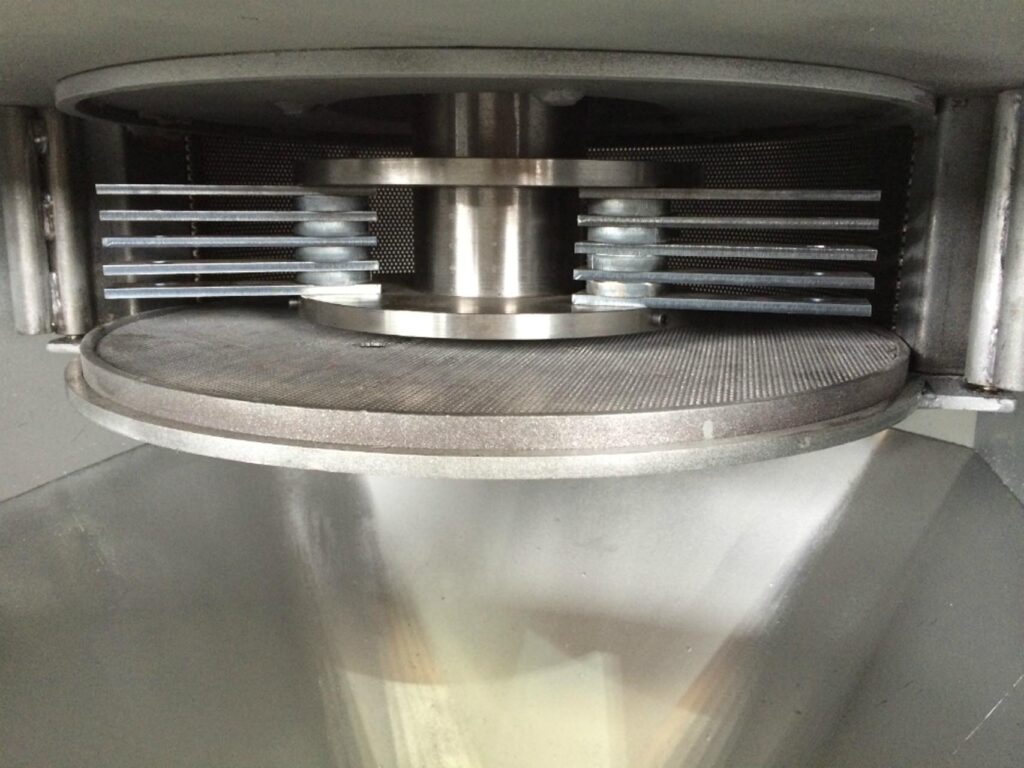

- Hammer mills contain a set of hammers, which rotate at high speeds in the mill, impacting on the product to be ground.

- The mill is made of construction steel, supported on 4 legs. Low noise and vibration level.

- Incorporates circular sieves that are easy to extract and incorporate.

- The set of hammers is bidirectional, with rotation to the right or to the left. To take full advantage of the hammers and sieves.

- Side gates with easy access to the rotor to control and change the hammers or sieves.

- Magnets with inspection records at the product entrance.

- Automatic feeder, with two product inputs to the mill.

- It incorporates a frequency variator to automatically regulate the optimal and uniform grinding, with the lowest possible consumption.

- Drive by direct motor.

Benefits:

- Low maintenance.

- Wide range of applications.

- Good accessibility to the grinding chamber.

- Quick replacement of hammers.

- Wide screening surface.

- Low level of noise and vibrations.

- High energy efficiency motor.

- Special anti-wear alloy hammers.